That inkjet’s surge in all areas of printing is unstoppable is now a fact. Initially confined to a pool of specific application sectors, once this technology had the numbers to expand beyond the more established application circuits, it rattled our world as we knew it creating a clear juxtaposition between analogue and digital.

Unprecedented partnerships and collaborations have been sparked between offset giants and vendors historically recognised as inventors and pioneers of digital printing technologies. Partnerships that have allowed us to join forces, expertise, resources and R&D, breathing life into the first digital presses and a new generation of production systems.

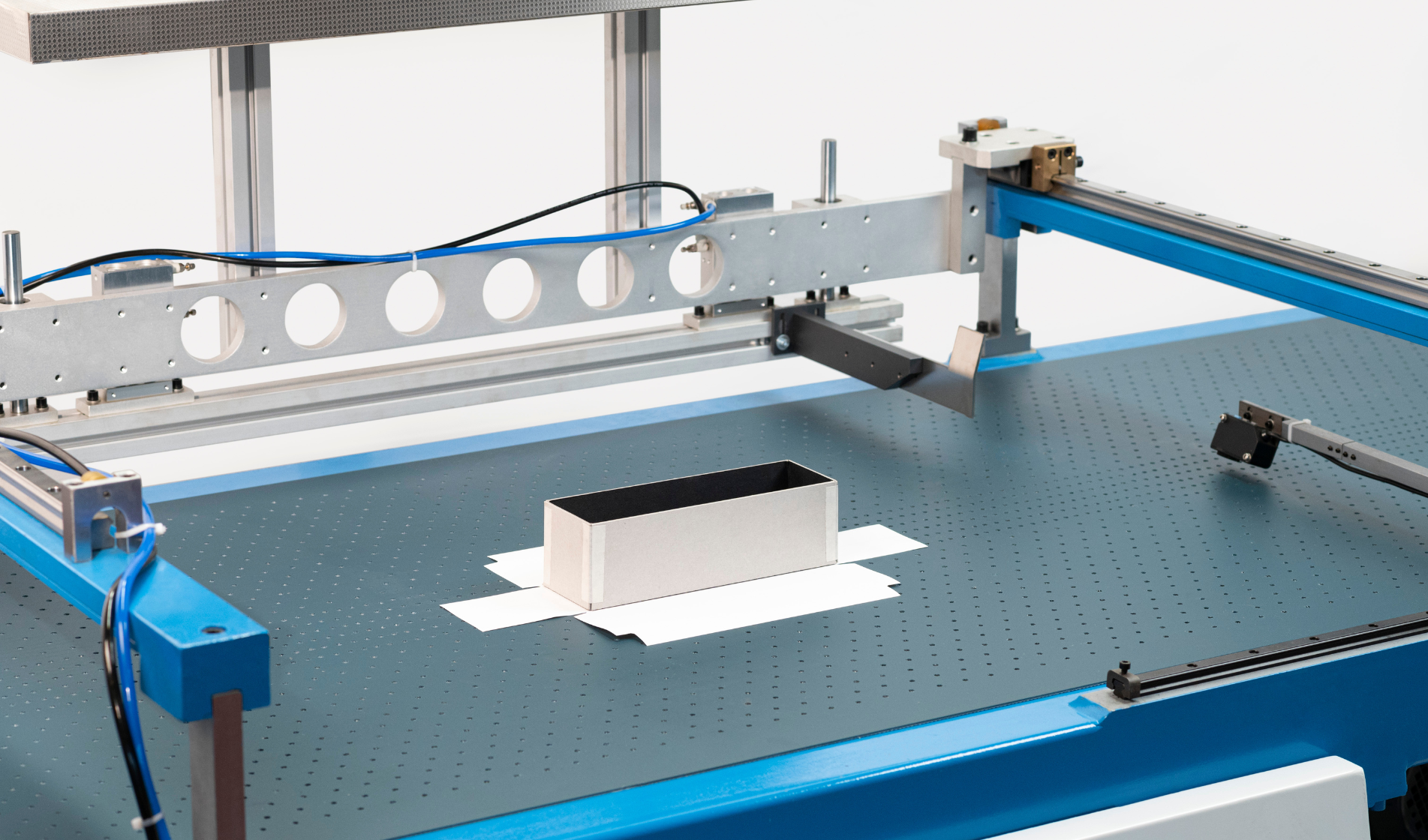

Just like in the automotive industry, machine evaluation is primarily based on speed, an aspect that, alongside quality, was one of the first to spark the age-old contest between offset and inkjet production. The evolution of inkjet was immediately fine-tuned, touching on elements other than the crucial one, productivity. We are talking about increasingly precise and high-performance printheads in terms of DPI, technologies that optimise paper paths associated with patented drying systems enabling greater stability and precision. But we are also talking about automated loading systems, precise feeders, finishings and in-line finishing. Formats have evolved to offer increasingly flexible solutions, emulating those provided by offset, screen, flexography and sometimes even gravure.

From UV to sublimation printing, from labelling and edible inks to water-based ones. These days identifying a medium that can’t be printed with inkjet technology is almost a challenge: paper and cardboard, including corrugated; any fabric type; all plastics, from flexible to rigid; wood; composite materials; glass; ceramics; metals and many more. On top of that, you can even customise ready-made items like mugs, suitcases, glasses, sheets, pillows and shoes. The application sectors are therefore infinite, from editorial and commercial graphic printing, photobooks, packaging and labels to fashion and design, from interior decoration to OOH. And what about vehicle décor? Anything can be customised, from scooters to airliners... Even food gets a look in: surely you’ve eaten a cake, biscuit or chocolate with inkjet printing? Not to mention art, which deserves a chapter onto itself. Right up to industrial printing in all its infinite forms, some of which see hybrid solutions using inkjet heads in complex printing systems or within industrial production processes that were unfathomable just a few years ago. Where production costs were still a variable that tipped the analogue-digital scales, for certain application types single-pass has paved the way for optimisation even on medium runs. Customisation is the magic word that’s made inkjet printing its fortune in several fields where it’s become established and will continue to do so, though the freedom to print a different piece without the fixed costs of sheets and engraving plates has played a part.

A challenge that will see increasingly wide-ranging, unexpected opportunities by riding the green wave thanks to solutions being developed that use water-based inks, exploiting technologies designed to allow printing on natural and uncoated media. And that means having as low an environmental impact as possible.