Post-printing and finishing are the phases that make printed material a product. Binding, packaging and finishing machines in general boast a panorama of technology and innovation.

The processes applied to printed materials after printing itself are essential to the creation of a finished product. A book is not a book until it has a bound cover, a direct mailing product will not arrive at its destination if it is not inserted into an envelope. Packaging is not packaging until after die cutting and folding. The post-printing phase is just as important as the phases that precede it. These are complex production processes, in which printing, post-printing, paper converting and technology companies continue to invest and innovate machinery and product.

The evolution of finishing systems is similar to that of other products in the printing industry. Low print runs, on-demand printing, personalisation and fast time to market - all these have driven printers to find solutions which optimise time and quality, in post-printing as in printing itself. These include the continued growth of automation, the ever more common use of inline finishing and the new possibilities offered by foils and other special effects.

Post-printing automation

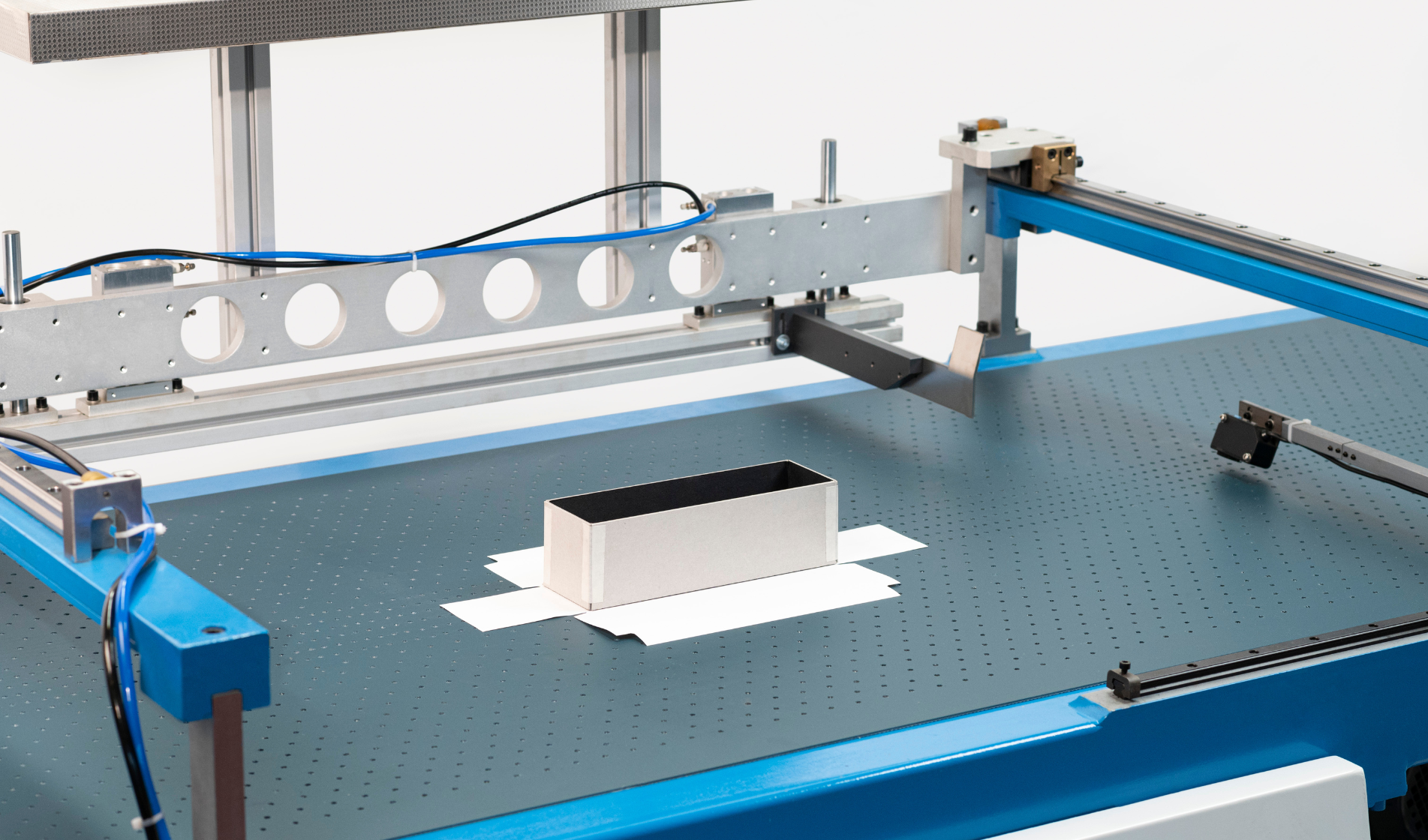

Like other print production processes, finishing has seen a fast growth in the demand for automated work flows. A number of tools are available to improve order tracking and reduce the number of quality controls and speed up production. The most commonly used finishing processes - cutting and folding - are also the most highly automated ones. A survey run by Keypoint Intelligence – Infotrends in North America reports that 63% of printers use automated cutting and 55% automated folding. These numbers are certain to grow with the increasing acceptance of artificial intelligence as a tool for optimising and adding value to processes.

Offline and inline finishing

The majority of finishing is still done by offline equipment, but there are many valid reasons for choosing inline finishing. Low cost and higher productivity are the most common reasons, as reported by Infotrends. Inline finishing allows two functions to be handled by a single operator, and eliminates the time spent moving printed material between machines. 46% of respondents said that they give priority to this potential for cost reductions. Productivity is the second reason for choosing inline finishing, with 43% of respondents indicating that inline equipment has a higher throughput.

So far, automation has been of greatest interest in simpler processes like folding, cutting and creasing. Solutions for more complex jobs (paper covering, printing on foils, embossing) are still costly and may have limited compatibility with different printing machines (according to 13% of respondents). Working offline is also the most feasible option when a variety of substrates or sheets from different printers are being used.

Digital foils and special effects

The emergence of digital foils has made metallic graphic finishing more accessible than ever. Traditionally, printing on foil was one of the most commonly outsourced finishing processes for commercial print shops, with 46% of respondents to the survey saying that they had outsourced such jobs. What will happen in the near future will also depend on the development of digital graphic finishing systems (digital screen printing, as some people call it). This promises to be a big new market for printing system and materials suppliers.