With a hybrid press, you could have it all. It could potentially solve the conundrum in label and pack- aging print of customers demanding ever shorter runs but squeezing prices at the same time.

The evolution of hybrid presses

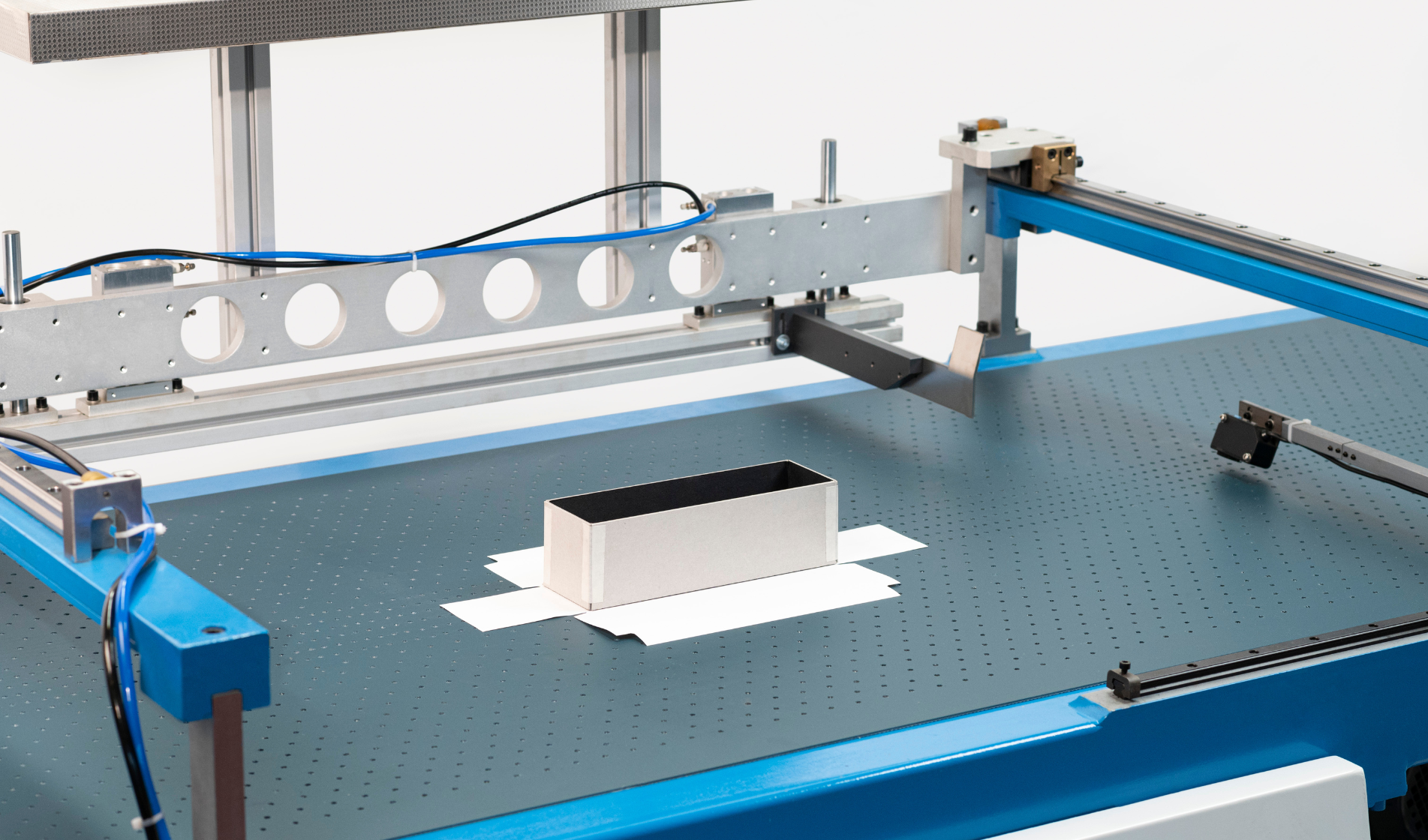

Hybrid presses combine inkjet and analogue technology. Strictly speaking, a hybrid press can consist of an inkjet unit and inline finishing only In most cases, the term refers to an inkjet unit with added flexo printing units, however. The flexo units can be equipped as pre- or postprint stations. The combination can be useful to print static portions in flexo, using lower-cost flexo ink. Only the variable portions or full-colour images are printed in inkjet. Furthermore, sometimes there are no extra inkjet colours available beyond CMYK, and those can be printed in flexo. This could include metallics or functional inks. Also, preprinting solid whites in flexo is more cost-effective than using inkjet. If mostly large areas are printed in inkjet, the approach loses appeal however, as in addition to the higher inkjet ink costs, plates are needed - including change-over time and waste. The ideal market for hybrid is versioning when large parts of the print remain static

For the first hybrid presses, inkjet units were simply added onto conventional flexo press lines with multi- ple flexo units and inline finishing. However, the first generation was not optimised for short runs and digital workflows: the analogue change-overs took too long, speeds & substrate ranges of the digital and analogue parts did not match and the digital unit did not communicate well with the analogue parts Suppliers did learn from the shortcomings. The latest models have a more modular design with a range of modules optimised for the analogue-digital interplay and include automation and in-line control features. Running the digital and analogue portions is now part of one operating concept, with a streamlined set-up.

Hybrid presses have the option for inline finishing. which can make the whole line very efficient-if finishing change-overs do not require too much downtime. This has been addressed recently as well, with finishing modules developed for fast change-over and less waste.

The printbar option

Another option for hybrid presses is integrating nkjet printbars, which can be used to convert existing flexo presses into a hybrid solution. A large range of vendors are offering different types of imprinting units or printbars. Printbars can be cost-effective when old equipment can be reused and only smaller digital image portions are required e.g., a monochrome imprint. If producing high-quality, full-colour applications it should be checked how well the conventional part is adapted for short runs and how well all the components can be operated in conjunction.

Hybrid in Label Printing

Digital print is already an established technology in label printing. Labels proved to be a fertile ground for digital print due to

· Smaller formats than other package prints - which is easier to achieve with digital printers;

· A higher portion of shorter runs than in other packaging markets, as labels are often used on products manufactured in small quantities;

· A substrate that is generally easier to handle than other types of packaging materials.

Most label volume is produced on dedicated roll- fed label printers. LT. Strategies reckons in their "Digital Production Label Market Review of 2020 report that there are almost 4,000 dedicated digital label printers in use by the end of 2020. The total share of all pressure-sensitive labels printed digitally is still relatively small, amounting to just over 6% of all label prints with a good portion using electrophotographic technology and a smaller portion using inkjet. Considering that inkjet hybrid presses for label printing came to the market more than 10 years ago, the volume share is still small, with about 6% of the digital label volume. Yet LT. Strategies expects hybrid press volumes to grow by 20% annually, due to the new generation of presses coming to the market.

Hybrid in packaging print

Other packaging market segments fall noticeably behind in the adoption of digital presses. Very few models are available in folding carton or flexible packaging so far. The market for corrugated inkjet presses is more established already, with 10 vendors and about 20 models available. Almost all models are inkjet-only presses, possibly with a flexo priming or varnishing unit. In any case, a hybrid approach in packaging print could make a lot of sense when static portions or large background solids can be combined with smaller digitally printed areas. This would lift the break-even for digital noticeably.

Choosing a hybrid press

Label printing is the application area with the highest number of press choices and this is not expected to change soon. More than 30 players are offering digital label printers, often with multiple models in the line-up, and new players are still entering the inkjet label press market. The choice is good news for buyers, although it can make selecting a device challenging. The choice of flexible packaging and folding carton presses is expected to increase soon, although market opportunities exist already.

Hybrid presses are not built for shortest runs, instead for mainstream print runs getting shorter to the point where an analogue press becomes inefficient. As they are modular, they can be tailored towards specific application requirements as well. Comparing device specifications is a start for selecting a press but it does not stop there. In addition to pricing, there are other factors vital in choosing the right device. The ease of operation and capabilities of the DFE are very important selection criteria and are best explored in person at a trade show or showroom. Furthermore, scrutinize the service and support a vendor can offer and the support in integrating a press in a full production line. In the end, hybrid presses are built to handle high monthly volumes. and accordingly optimising the whole workflow is critical.